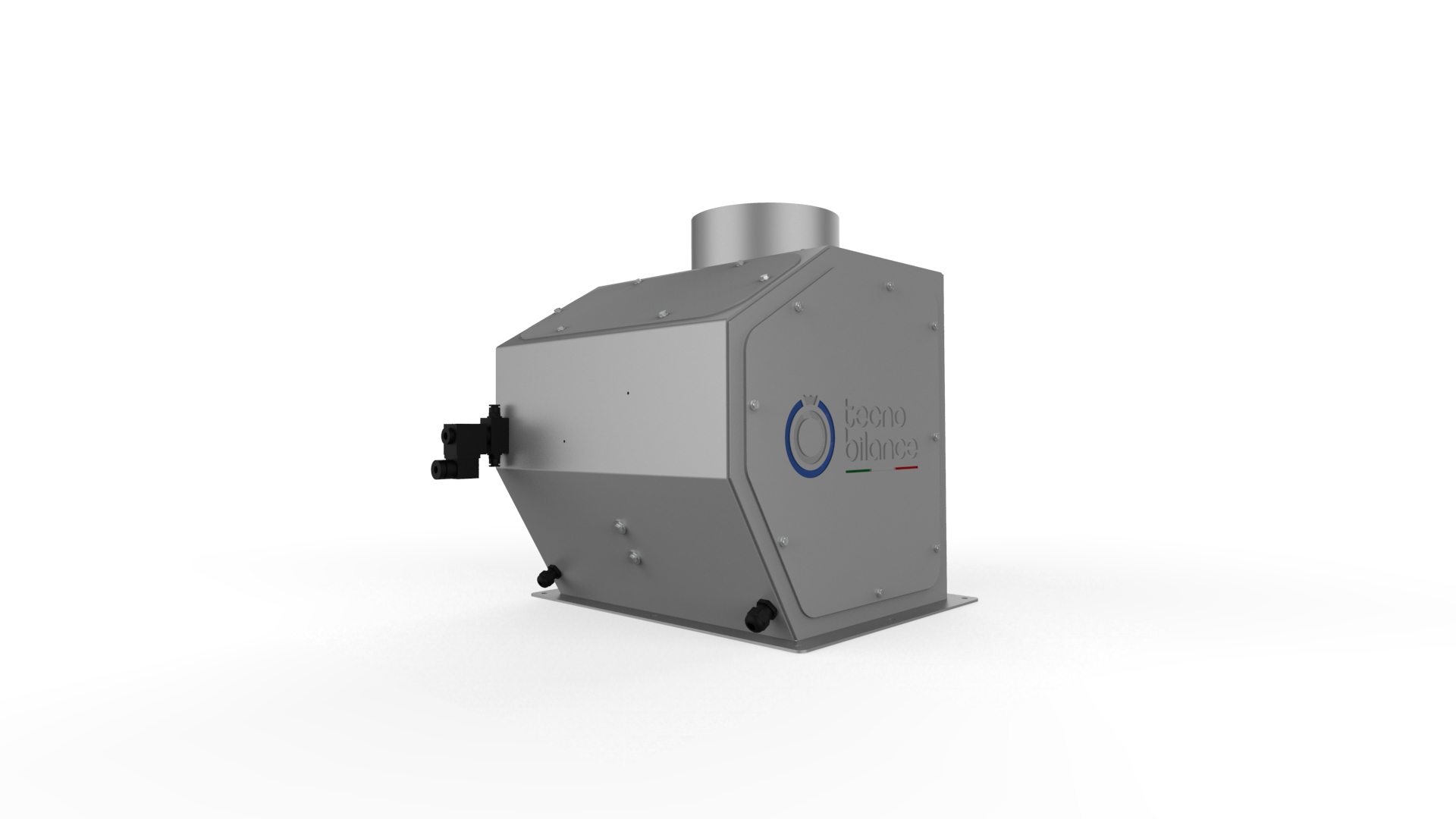

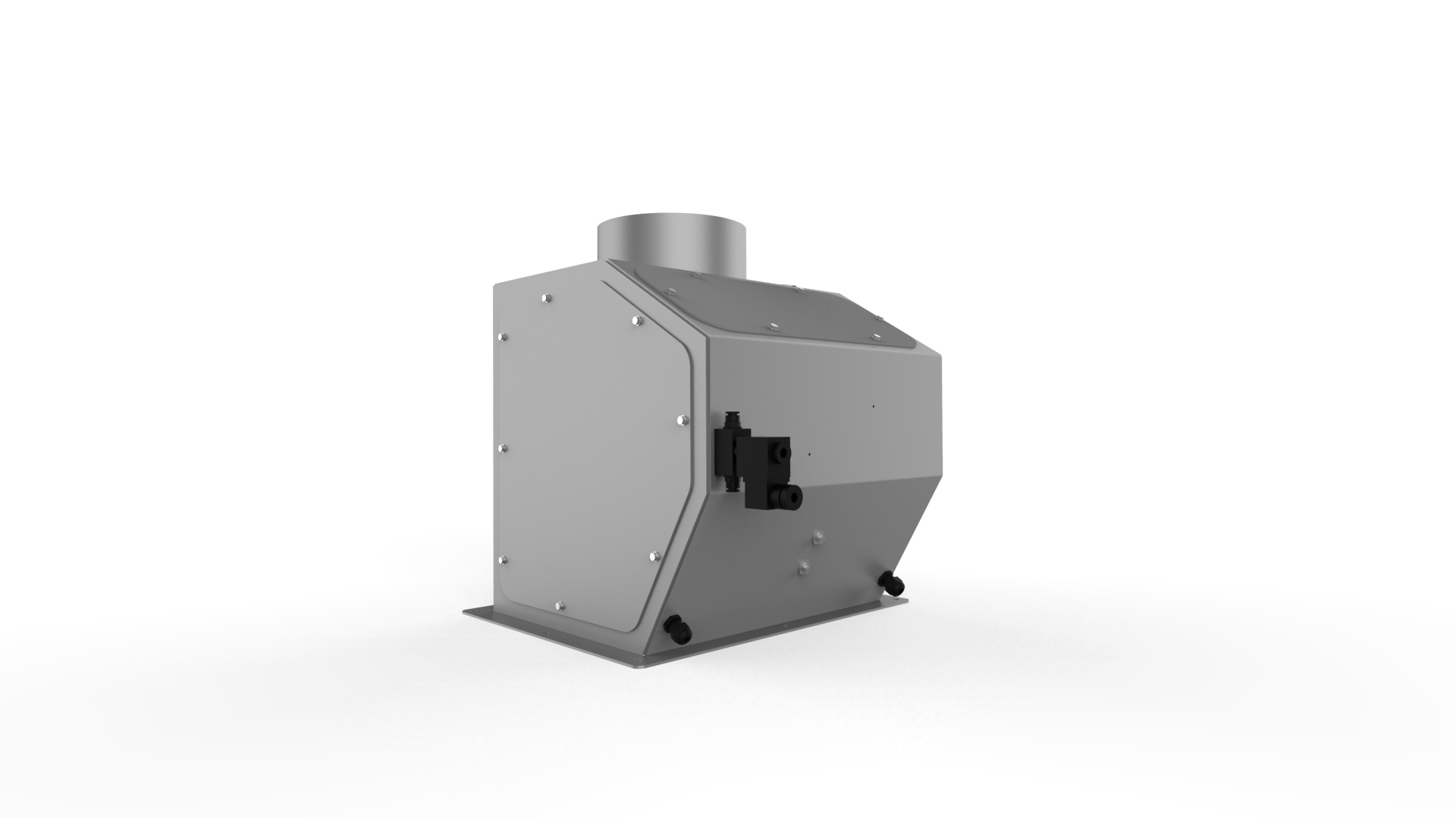

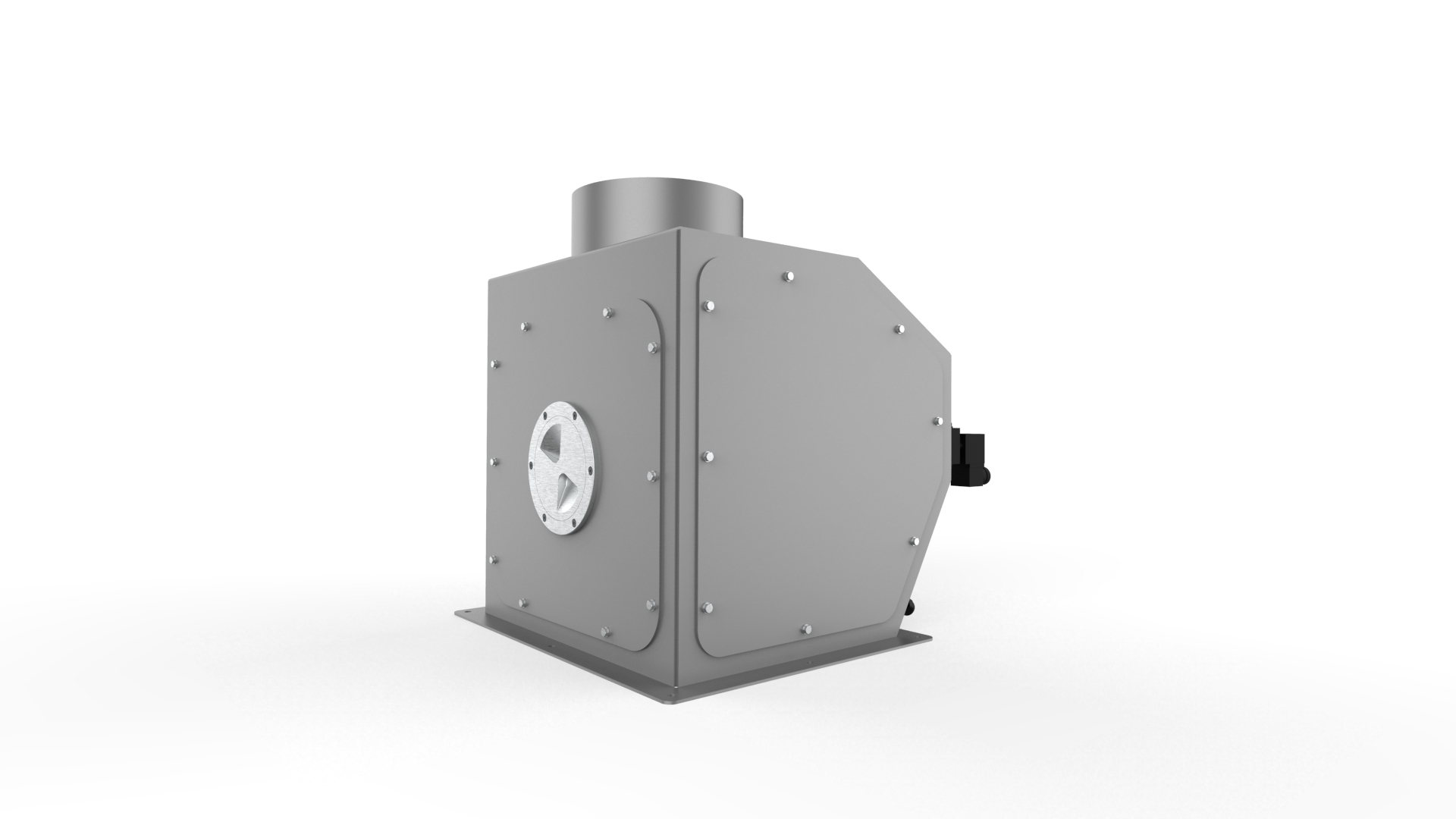

ADM - Automatic Dampening Machine

TecnoBilance

The operation of the machine is based on the detection of humidity in the product, in order to add the quantity of water necessary to obtain the required percentage of the final humidity. Moisture detection will be with microwave sensor. For the exact determination of the quantity of water to add, in addition to the humidity value, it is necessary to know the instantaneous flow rate of the product passing through the machine. This info is grant by the detection unit integrated into the device, based on the measurement of the impact force of the product flow plate and the load cell. The the correct quantity of water will be add at the cereal with the water panel in automatic mode or in manual mode.

Humidity reading

The current humidity value of the product is calculated in base of the microwave value transmitted by the measurement sensor, and of the product temperature. The temperature value is detected by a probe integrated in the humidity sensor. The final humidity value of the product is the humidity value that the product must have after dampening time in the silos then this value can be set locally from the touch screen or remotely via supervisor.

Water dosage

The automatic dampening machine, in base of the values of the sensors signals, set the position of the water regulation valve through the flow value detected by the flow meter mounted on the water panel, the automatic dampening machinewill operate the actuator by opening or closing the valve based on the amount of water calculated to obtain the required conditioning. The determination of the water flow to be supplied is a function of three fundamental parameters: product humidity value, product final humidity value, weight capacity value.

Communication with supervision system

The automatic dampening machine can communicate with a remote supervision system for the control, and permit the possibility to development of a flow analysis management system, yield calculation and storage of the totalizers.

The available protocols are:

- None (the machine works in “stand alone” mode)

- Modbus RTU (RS232) - SLAVE configured

- Modbus TCP (Ethernet) - SLAVE configured

- PROFIBUS protocol - Optional

- PROFINET protocol - Optional