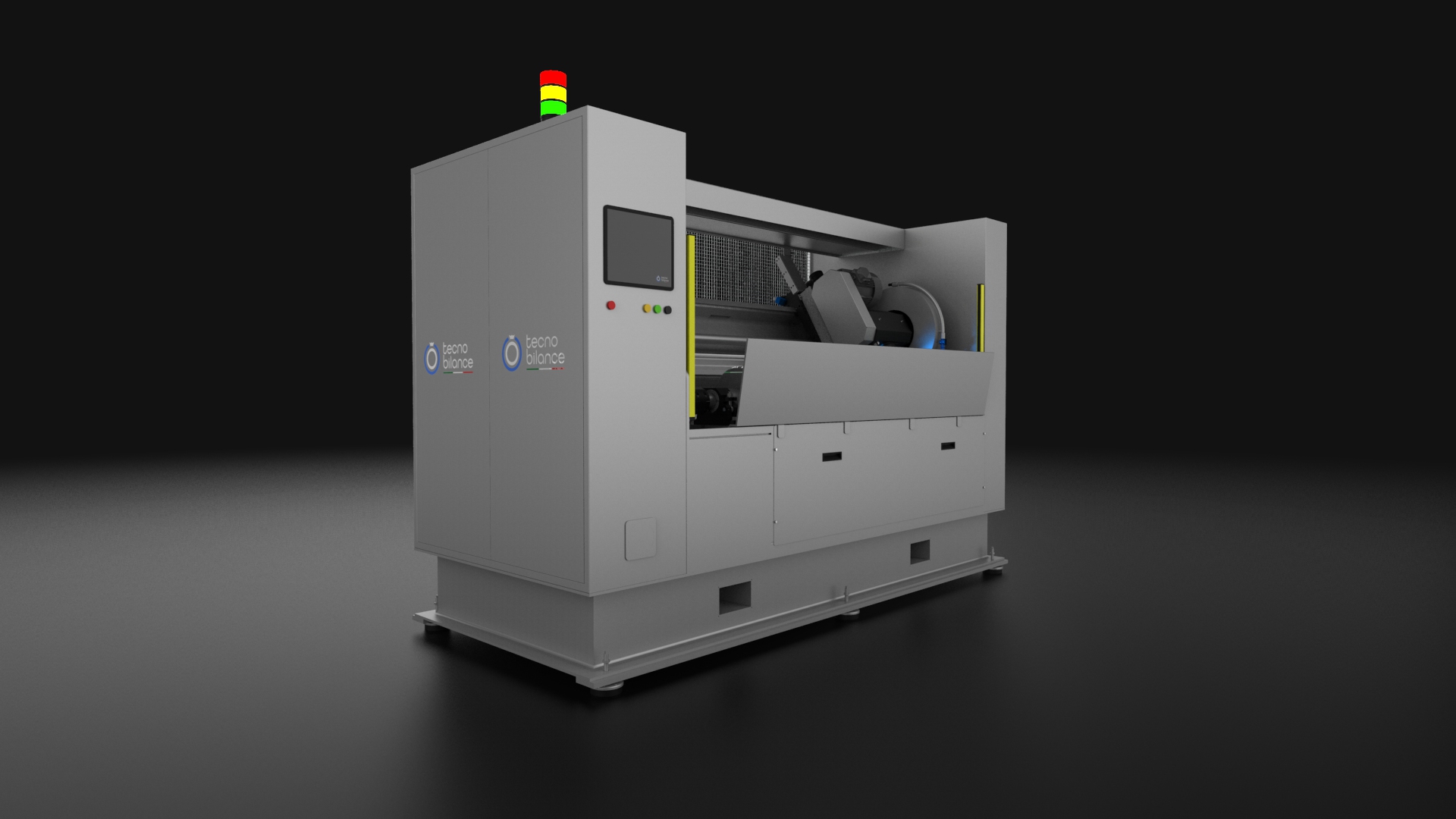

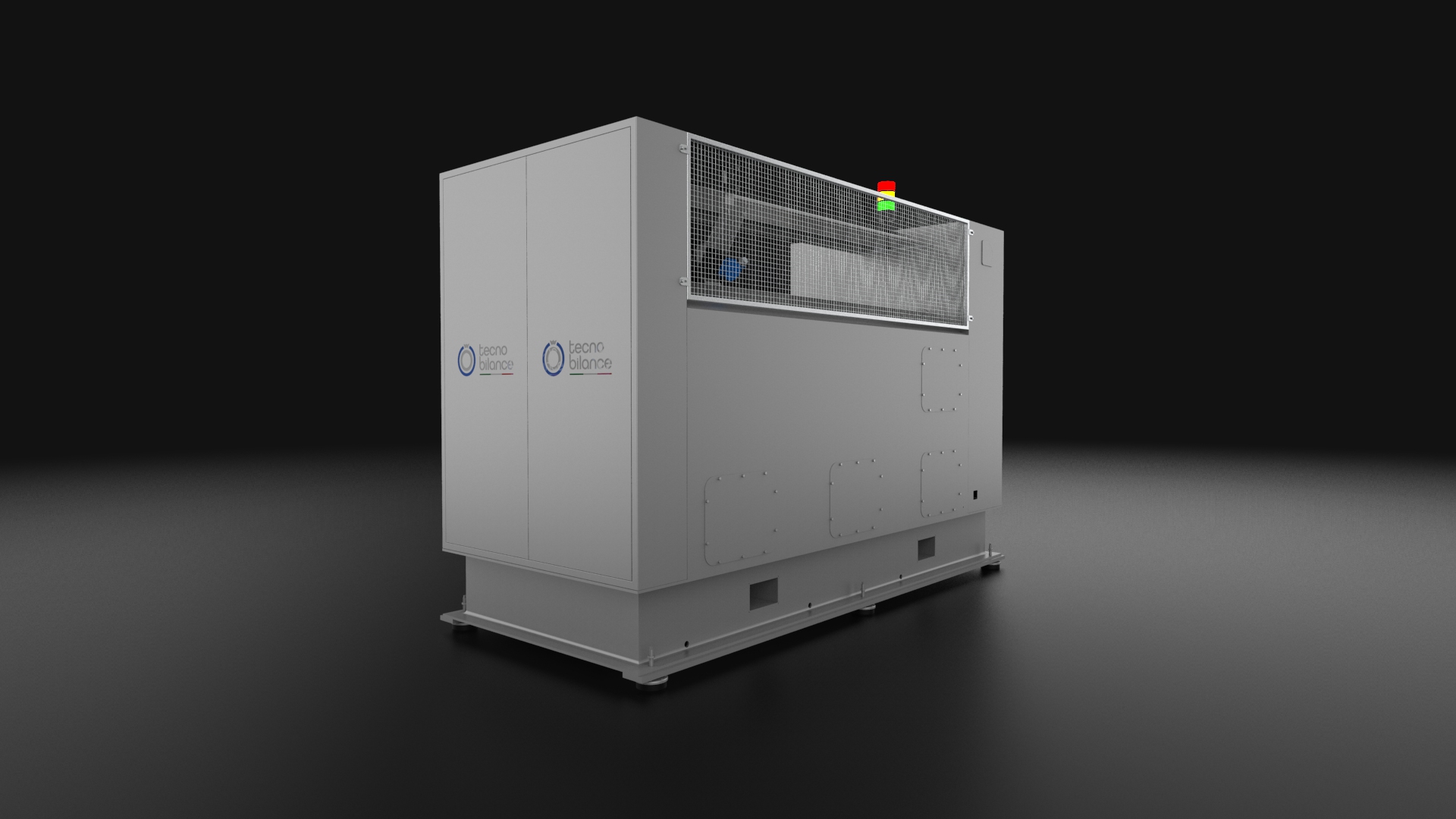

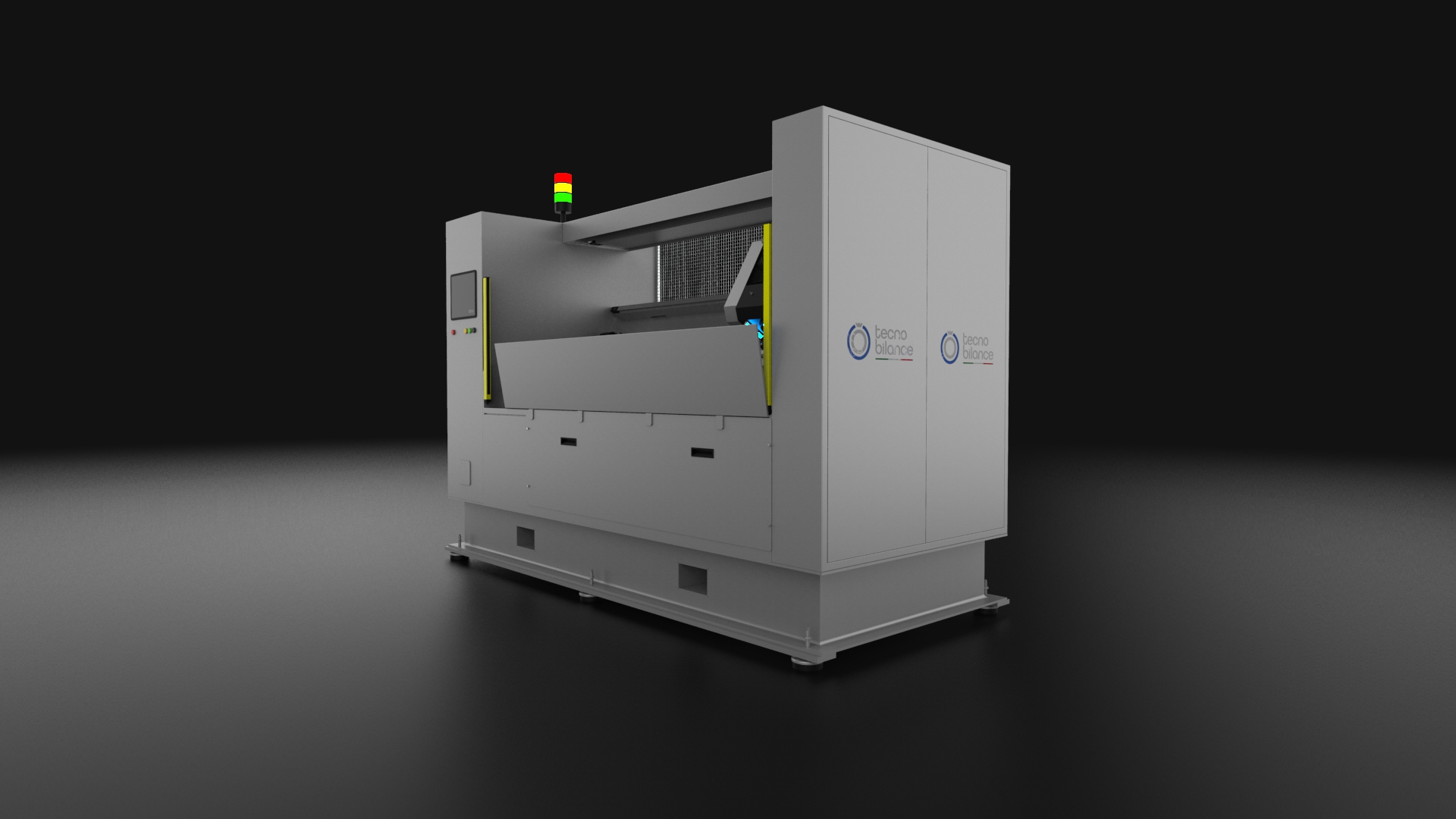

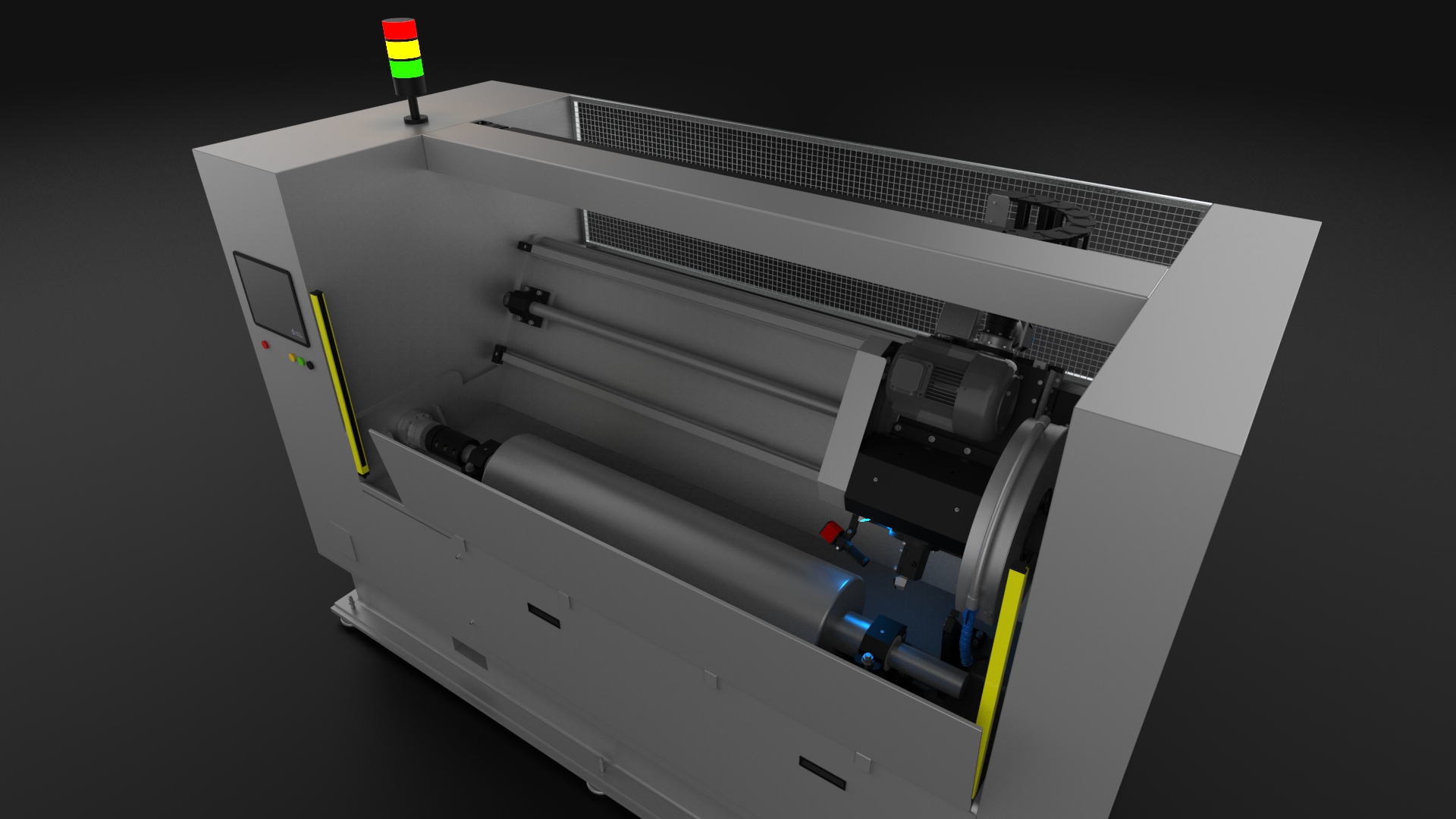

FGM - Fluting & Grinding Machine

TecnoBilance

The Fluting/Grinding FGM1250 is a CNC machine tool used for to restoring rounding, by grinding, and for profile regenerating, by fluting, mill grinding cast iron rolls used in milling industry. The machine use CNC controls for all the operational functions, in way to help the easy use and operations.

Available working cycles

The FGM1250 is able to work rolls up to a diameter of 300 mm and a length of 1250 mm, with following operation processing cycles:

- Cylindrical grinding

- Cambering grinding

- Cylindrical fluting

- Cambering grooving

- Execution of the lateral chamfers of the rolls

- Elimination of the existing fluting profile with cutting tool

- Maintenance of the grinding wheel.

Model

A

mm

B

mm

C

mm

Weight

kg

Max Roll Ø

mm

Grinding Length

mm

Shaft Ø

mm

Shaft Max Length

mm

Grooves

Helix Inclination

% sx/dx

Max Speed

m/min

Grinding Wheel Max Ø

mm

Grinding Wheel Min Ø

mm

Grinding Wheel Width

mm

Cooling Pump

l/min

Integrated Tank

l

Power Supply

AC

Power Consumption

kw

FGM1250

3000

1300

2000

3200

320

800 - 1250

60 - 80

350

5 - 3000

0 - 45

60/40

320

60

60

85

200

400 3F+PE

14

Products

Single Hopper Scale

01Single Hopper Scale V2

02Double Hopper Scale

03Micro Hopper Scale

04Loss Weight Feeder

05Flow Balance Machine

06Micro Dosing Feeder

07Simple Micro Doser

08Screw Conveyor Feeder

09Automatic Dampening Machine

10Pelican Sampler

11Fluting & Grinding Machine

12Sand Blasting Machine

13Laser Aided Profiler

14Model

A

mm

B

mm

C

mm

Weight

kg

Max Roll Ø

mm

Grinding Length

mm

Shaft Ø

mm

Shaft Max Length

mm

Grooves

Helix Inclination

% sx/dx

Max Speed

m/min

Grinding Wheel Max Ø

mm

Grinding Wheel Min Ø

mm

Grinding Wheel Width

mm

Cooling Pump

l/min

Integrated Tank

l

Power Supply

AC

Power Consumption

kw

FGM1250

3000

1300

2000

3200

320

800 - 1250

60 - 80

350

5 - 3000

0 - 45

60/40

320

60

60

85

200

400 3F+PE

14