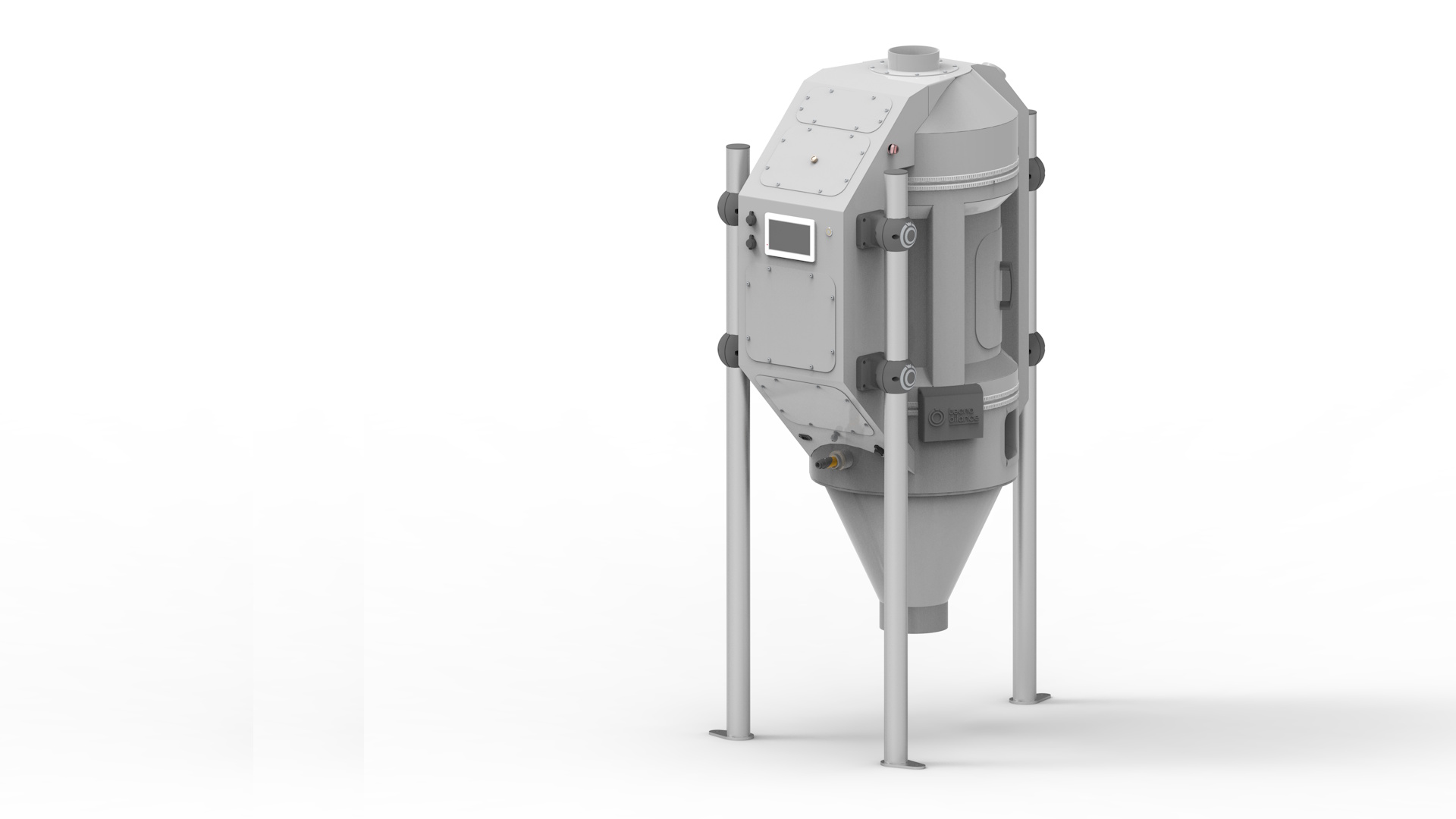

SH2 - Single Hopper Scale

TecnoBilance

TECNOBILANCE SRL presents the new tubular scale, more compact, precise, and efficient for weighing powdery and free-flowing granular products. Designed collaboratively by humans and artificial intelligence, SH2 combines human ingenuity, AI power, and 3D printing versatility to deliver maximum accuracy and reduced air consumption, surpassing the performance of any other scale in its category.

Through advanced engineering techniques, SH2 optimizes production processes, reduces waste, and ensures intelligent and dynamic control.

The new SH2 scale adds to the precision of load cells a powerful differential pressure control algorithm between product loading and unloading.

- More compact.

- More precise.

- More efficient.

“SH2/C” the cutting-edge check weighing scale

Optimize your production processes with our latest generation check weighing scale! Thanks to instantaneous flow rate measurement and precise counting of the total product quantity, you can:

- Monitor material flow in real-time.

- Ensure maximum accuracy in your operations.

- Reduce waste and increase efficiency.

Ideal for various industrial sectors, our scale is the perfect solution for those seeking high performance and reliable results.

“SH2/D” precise control and optimized production with our regulation scale!

Maximize your production line efficiency with our state-of-the-art regulation scale. Thanks to automatic flow rate adjustment based on the desired set-point and accurate counting of the total product quantity, you can:

- Maintain consistent and precise production.

- Minimize waste and errors.

- Optimize production times.

- Have total control over material flow.

Perfect for the food, chemical, pharmaceutical, and many other industries, our regulation scale is the ideal solution for those seeking precision and reliability.

Communication with the supervision system

The SH2 scale allows communication with a remote supervision system for machine control and data reading, enabling the potential development of a management system for flow rate analysis, yield calculation, and totalizer storage. The available protocols are:

- None (the machine operates in "stand-alone" mode)

- Modbus RTU (RS232) - SLAVE configured

- Modbus TCP (Ethernet) - SLAVE configured

- PROFIBUS protocol - Optional

- PROFINET protocol - Optional